Best of the Best

Best of the Best Food Safety Before Refrigeration

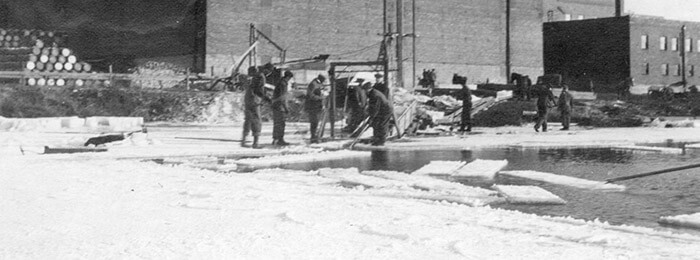

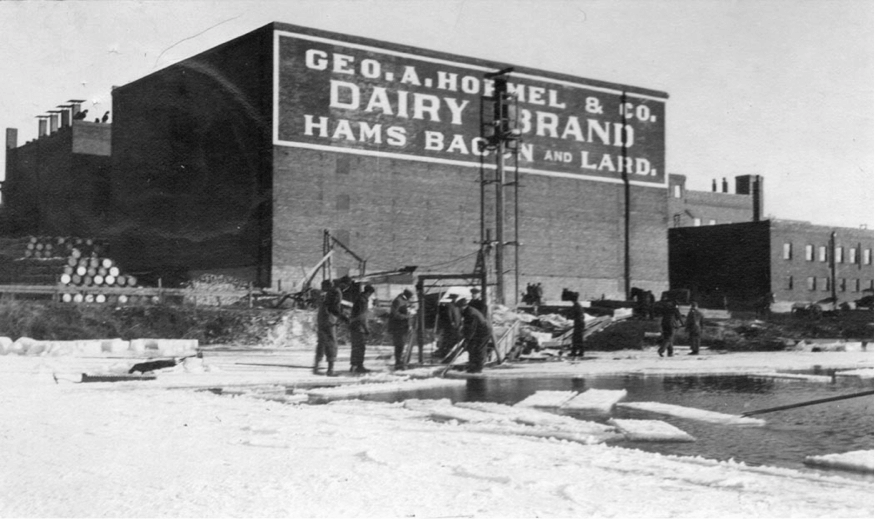

At the turn of the century, one major challenge for meatpackers was refrigeration. Harvesting blocks of ice from lakes and rivers was the most common method of keeping meat and food products cold and fresh. It was no coincidence in 1891 that George A. Hormel located his packing operation along the Cedar River in Austin, Minn.

In the company’s early years, all the employees took turns harvesting ice. Later, ice gangs were organized to allow full-time employees to stay focused on their normal duties. Hand saws were used to cut the ice blocks, which usually measured 12-18 inches thick. By 1912, the plant was harvesting more than 22,000 ice blocks each winter, weighing a combined total of 7,400 tons. Ice harvesting continued at the plant until 1936 when the company began to experiment with artificial ice-making equipment.

While this was the commonly utilized method of refrigeration at the time, the company was ahead of the game in other food safety practices. George A. Hormel had believed in producing the highest quality products from the company’s inception, prior to any federal inspections. As Hormel had maintained that it was better to do things right the first time, the company received stellar marks on its first federal food safety inspection.

The company’s dedication to quality continues today as part of our company vision:

“Building upon our heritage of innovation and quality, together we will elevate the everyday experience by making Hormel Foods the favorite part of any eating occasion.”